Product Description

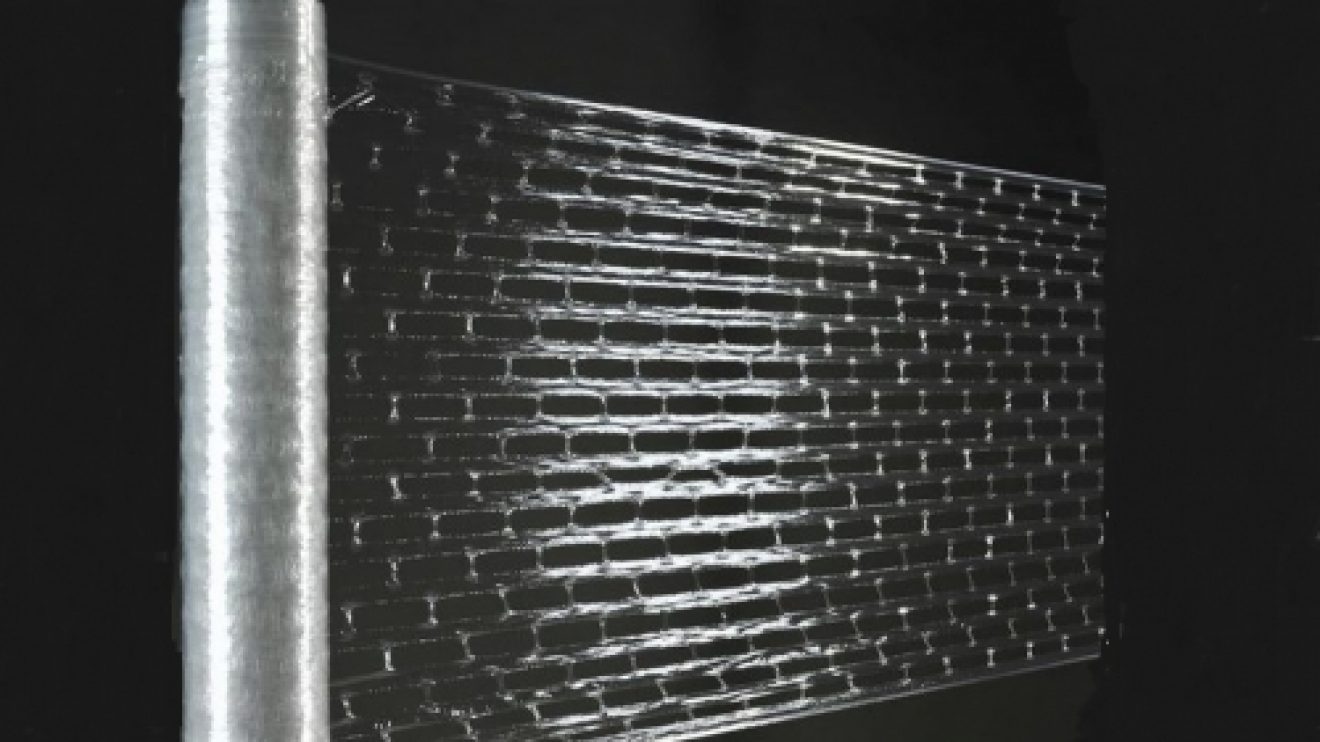

Macro Air Film is a macroperforated stretch film designed to facilitate maximum ventilation: due to its structure it allows to circulate as much air as possible, up to 60%.

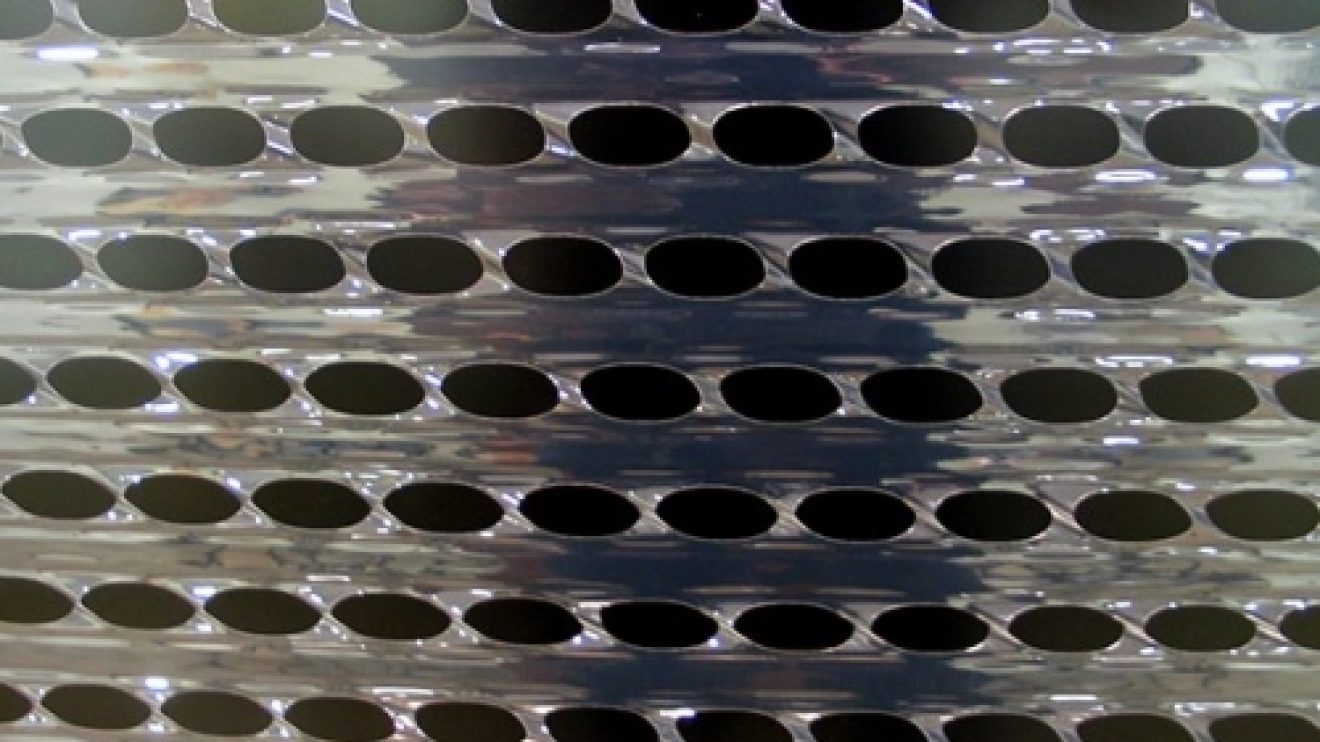

The holes can be of different sizes according to the level of support and ventilation that is needed according to the palletized product. These holes also have an extra reinforcement to give a perfect stability to the pallets.

The macroperforated stretch film allows the palletized goods to be kept cold, dry and at a constant temperature. For products wrapped whilst warm, such as juices, beers, food, ceramics, etc., the holes allow unrestricted cooling and eliminate accumulated heat during the production process, thus avoiding condensation problems.

On the other process, in products that are palletized at low temperatures or that have to pass through cooling tunnels or cold chains such as ice creams, yoghurts, fish, meat, and the like, the holes reduce the cooling or freezing time of the load by allowing the cooling process to be faster and cheaper.

It is produced 100% with recyclable polyethylene, and is suitable for manual application and automatic or semiautomatic wrappers.

The macroperforated stretch film has been designed to provide an excellent fastening to the palletized product, using less plastic, so by using less plastic we save a lot of money on the palletizing.

It allows:

• Excellent ventilation

• Constant temperature of your products

• Fast cooling and Fast drying

• Excellent stability of the pallets

• Vegetables and plants can breathe normally.

• Less energy required to cool or freeze the goods in the pallets

It avoids:

• Avoids condensation and all associated problems.

• Reduce the risk of bacterial infections, fungi, etc.

• Avoid overheating the products (for example: frozen foods, meat, ice cream, eggs and similar)

| It prevents condensation, thereby preventing oxidation of cans and closures, and deterioration of product labeling, which maintains its original appearance. |

For palletizing cold or frozen

| It reduces the freezing time as the cold air affects the product faster. It reduces freezing time since moisture disappears before. |

For palletizing of fruit, vegetables and plants

| Air circulation ensures optimal product protection, and keeps fresh for longer. |